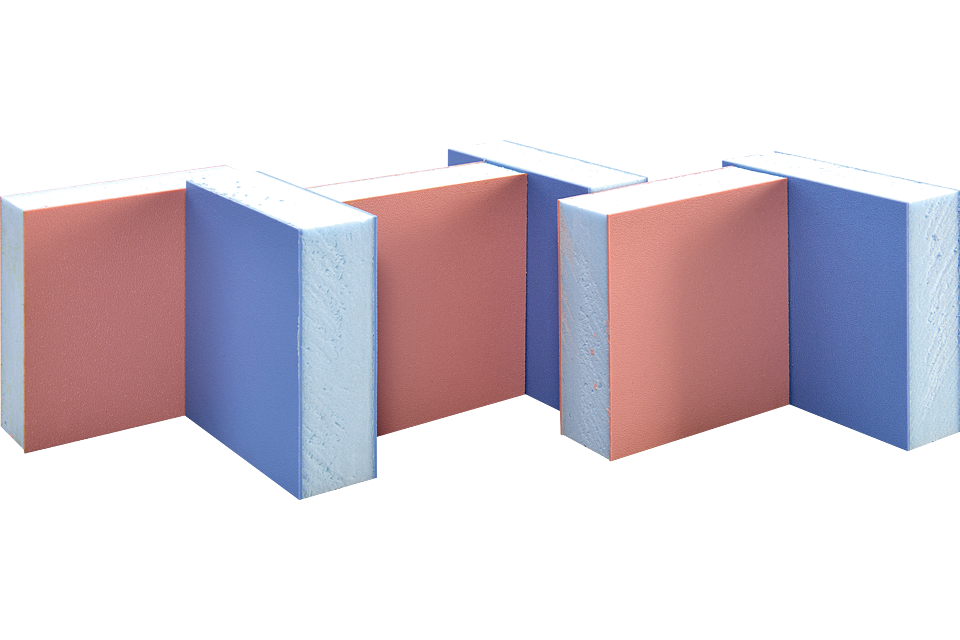

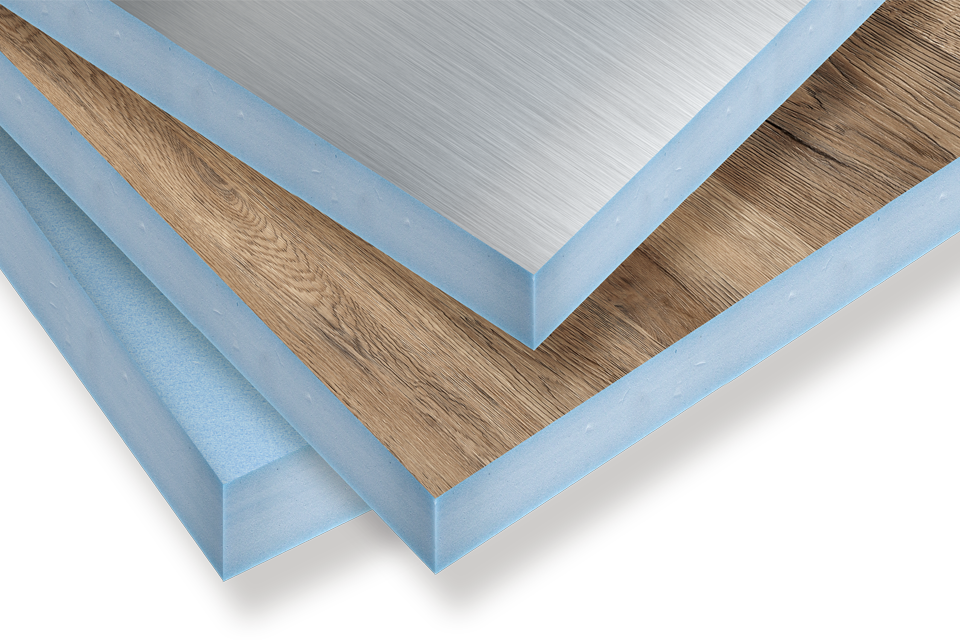

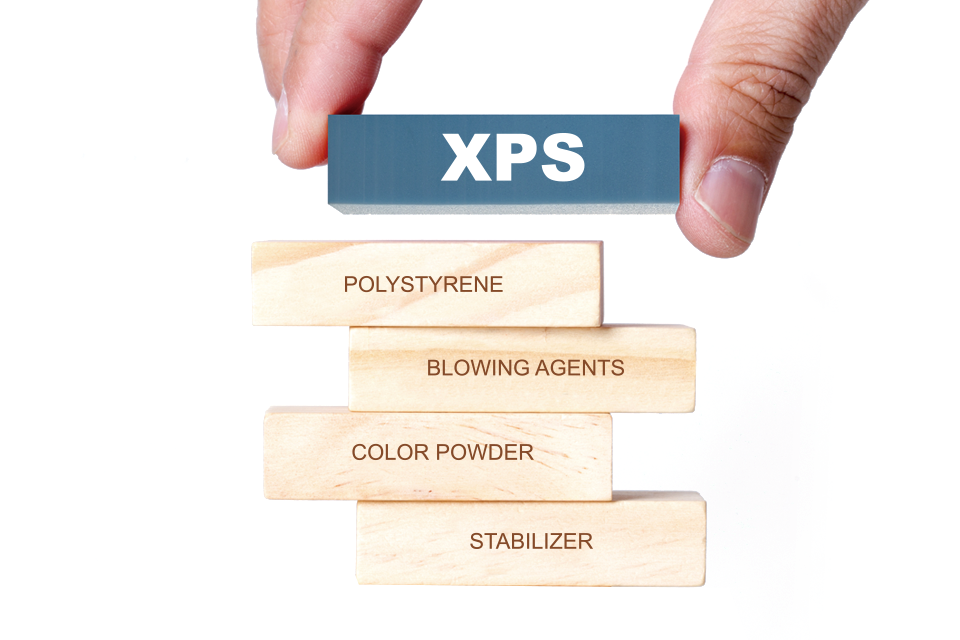

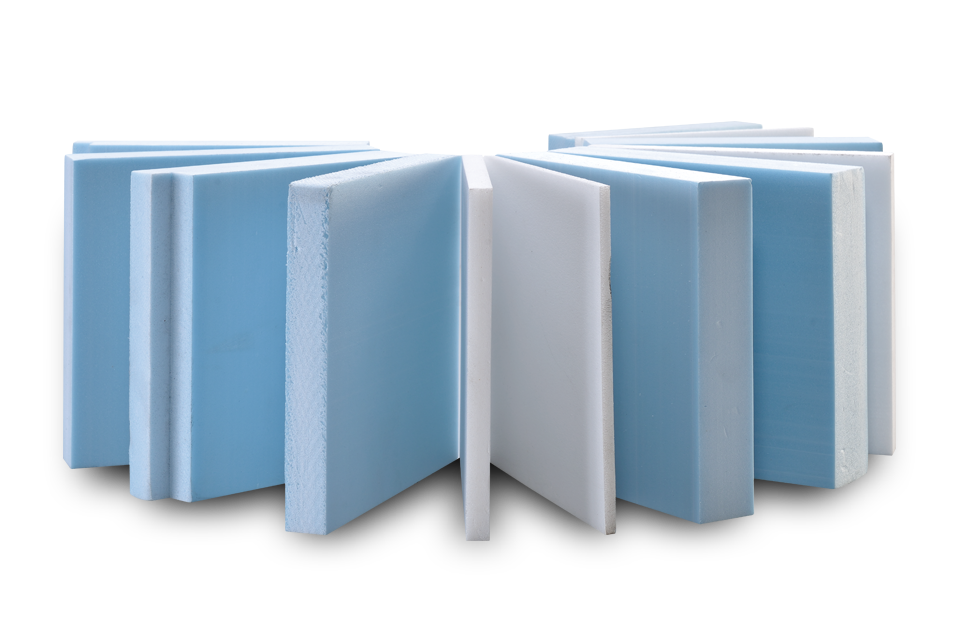

XPS foam heat insulation board

XPS foam heat insulation board

Remarks: The thickness of color 5, 7, 10m/m are mainly in white and above 15m/m are light blue respectively.

Specification is subject to customers’ need.

Specification is subject to customers’ need.